International 584 cumpărați folosit (10.547)

Baden-Württemberg

Baden-Württemberg Micrometru interior digital cu trei puncte

MITUTOYOMicrometer

Baden-Württemberg

Baden-Württemberg Micrometru interior digital cu trei puncte

BOWERSHOLEMATIC

Baden-Württemberg

Baden-Württemberg Micrometru interior digital cu trei puncte

BOWERSHOLEMATIC

Kobenz

Kobenz Mașină de tăiat filet interior M3-M16

VOLUMECJT3150

Mielec

Mielec Mașină de rectificat interior și de suprafață

TripetTST201 CNC

Descoperiți mai multe utilaje second-hand

Germania

Germania Utilizat Star SA-16-12 an fabr. `00_(IntNr231493)

STAR MicronicsSA 12/16

Eilenburg

Eilenburg Mașină de rectificat interior și fețe

WMWSI 6/1 x315

Monheim am Rhein

Monheim am Rhein Mașină de rectificat interior și fețe

GLAUCHAUSIP 400x500

Korschenbroich

Korschenbroich Mașină de broșare internă CNC

FORSTRISH 6.3X1000X320

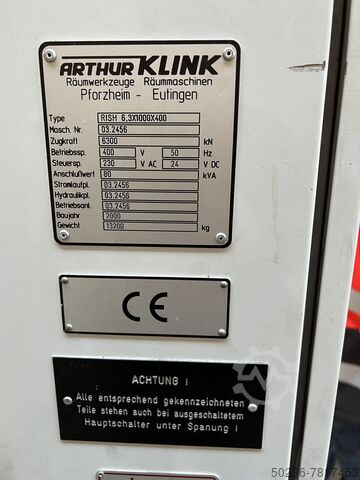

Korschenbroich

Korschenbroich CNC în interiorul mașinii de broșare

Arthur KlinkRISH 6.3X1000X400

Germania

Germania Mașină de rectificare internă

OVERBECKZettos 30

Dreieich

Dreieich Mașină de broșat - Interior - Orizontală

HAHNDORFHRY 1200

Beringen

Beringen Mașină de rectificare internă

VOUMARD5A

Langenfeld (Rheinland)

Langenfeld (Rheinland) Mașină de rectificat interior și fețe

BuderusCNC 235

Hilden

Hilden Mașină de rectificat interior și de suprafață

WEMA GLAUCHAUSBZ 6-F

Stuttgart

Stuttgart Mașină de rectificat interior și fețe

StuderS145

Germania

Germania Deckel Maho DMF 250 linear an fabricație 2004, Nr. intern 231486

DMGDMF 250

Offenbach an der Queich

Offenbach an der Queich Mașină de rectificare internă

VOUMARD400 CNC U2 L10 T2

Mudersbach

Mudersbach Mașină de filetat interior

Easy TapETH 24

Hessisch Lichtenau

Hessisch Lichtenau Pompă hidraulică ES pentru TRUMPF TC 500 R, set piesă de schimb original Trumpf nr. 1737140 pompă cu

BOSCH REXROTHP2GH3/011+GH3/013RE47+47U2-A502

Striegistal

Striegistal Mașină de broșat vertical intern

Karl KlinkRISZ 25/630

Striegistal

Striegistal Mașină de broșat vertical intern

Karl KlinkRISH 16.1000.630

Germania

Germania Mașină de honuit - Interior - Vertical

Werkzeugmaschinenfabrik Frunse2A78

Linz

Linz XEROX C60 cu FIERY EX-i C60/70 intern

XEROXXEROX Digital Color Press C60

Dorsten

Dorsten